Glass Bead vs. Aluminum Oxide Abrasives

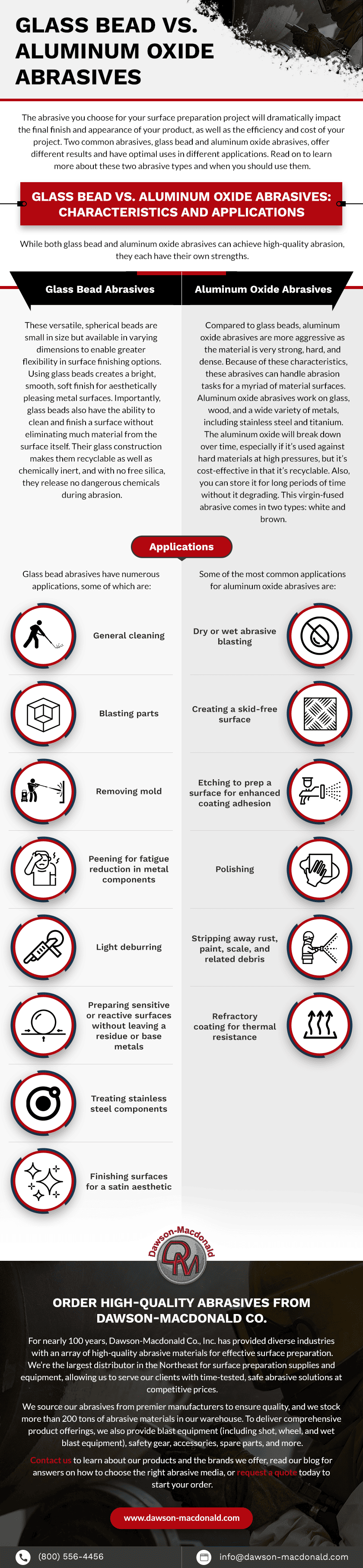

Leave a CommentThe abrasive you choose for your surface preparation project will dramatically impact the final finish and appearance of your product, as well as the efficiency and cost of your project. Two common abrasives, glass bead and aluminum oxide abrasives, offer different results and have optimal uses in different applications. Read on to learn more about these two abrasive types and when you should use them.

Glass Bead vs. Aluminum Oxide Abrasives: Characteristics and Applications

While both glass bead and aluminum oxide abrasives can achieve high-quality abrasion, they each have their own strengths.

Glass Bead Abrasives

These versatile, spherical beads are small in size but available in varying dimensions to enable greater flexibility in surface finishing options. Using glass beads creates a bright, smooth, soft finish for aesthetically pleasing metal surfaces. Importantly, glass beads also have the ability to clean and finish a surface without eliminating much material from the surface itself. Their glass construction makes them recyclable as well as chemically inert, and with no free silica, they release no dangerous chemicals during abrasion.

Glass Bead Abrasive Applications

Glass bead abrasives have numerous applications, some of which are:

- General cleaning

- Blasting parts

- Removing mold

- Peening for fatigue reduction in metal components

- Light deburring

- Preparing sensitive or reactive surfaces without leaving a residue or base metals

- Treating stainless steel components

- Finishing surfaces for a satin aesthetic

Aluminum Oxide Abrasives

Compared to glass beads, aluminum oxide abrasives are more aggressive as the material is very strong, hard, and dense. Because of these characteristics, these abrasives can handle abrasion tasks for a myriad of material surfaces. Aluminum oxide abrasives work on glass, wood, and a wide variety of metals, including stainless steel and titanium. The aluminum oxide will break down over time, especially if it’s used against hard materials at high pressures, but it’s cost-effective in that it’s recyclable. Also, you can store it for long periods of time without it degrading. This virgin-fused abrasive comes in two types: white and brown.

Aluminum Oxide Abrasive Applications

Some of the most common applications for aluminum oxide abrasives are:

- Dry or wet abrasive blasting

- Creating a skid-free surface

- Etching to prep a surface for enhanced coating adhesion

- Polishing

- Stripping away rust, paint, scale, and related debris

- Refractory coating for thermal resistance

Order High-Quality Abrasives From Dawson-Macdonald Co.

For nearly 100 years, Dawson-Macdonald Co., Inc. has provided diverse industries with an array of high-quality abrasive materials for effective surface preparation. We’re the largest distributor in the Northeast for surface preparation supplies and equipment, allowing us to serve our clients with time-tested, safe abrasive solutions at competitive prices.

We source our abrasives from premier manufacturers to ensure quality, and we stock more than 200 tons of abrasive materials in our warehouse. To deliver comprehensive product offerings, we also provide blast equipment (including shot, wheel, and wet blast equipment), safety gear, accessories, spare parts, and more.

Contact us to learn about our products and the brands we offer, read our blog for answers on how to choose the right abrasive media, or request a quote today to start your order.