What Is Automated Air Blasting?

New technologies continuously improve manufacturing processes, including air blasting and surface preparation. Automated blasting systems use automated or robotic nozzles to blast surfaces with abrasive materials. Various industries use this process for tasks like metal finishing and surface preparation to create a smoother finish. Automated blast systems consist of part handling, part manipulation, and blasting nozzle equipment.

Dawson-Macdonald provides automated blasting systems ranging from pre-engineered, standard blast automation to fully customized equipment to accommodate your needs.

How Does Automated Air Blasting Work?

Automated air blasting uses an air compressor to deliver an air/media mix at the desired volume and speed to impact the components to be processed. The air compressor’s pressure regulator increases or decreases the speed and pressure of the media delivery.

Suction-blast systems are the most common type of automated air blasting. In these systems, a suction-blast gun takes in a preset amount of compressed air through an air jet, creating a powerful vacuum that draws media particles through the gun, mixing them with the air and ejecting them out the nozzle. Pressure blast cabinets have a pressure pot that stores the blast media under high pressure. When released from this vessel, the air/media mix gathers speed through at least five feet of the hose and by traveling through the nozzle.

Components of Automated Air Blasting Systems

Common types of automated blasting systems include air blasting, suction or pressure, micro blasting, or wet blasting. The ideal blasting equipment will depend on your application needs, operating environment, budget, and production requirements.

While there are different types of automated air blasting systems, they share the same primary components.

Advantages of Automated Air Blasting Systems

There are many benefits to using automated air blasting equipment in manufacturing processes. Increased efficiency and reduced costs are two major reasons automated air blasting systems are gaining popularity. Automation helps reduce the number of people and resources required to create a final part, lowering operating costs and allowing employees to run multiple machines simultaneously.

Media flow controls

These media flow controls allow the media to be released onto the workpiece with unprecedented precision and accuracy. This media control technology has significantly increased efficiency and productivity for clients, allowing them to achieve superior end results faster than ever before.

Recovery and classification

The automated classification portion takes that further by precisely controlling critical parameters to achieve optimal finishing results. This automation ultimately leads to improved surface preparation quality and repeatability, resulting in higher yields and fewer rejects.

System validation

Our air blast equipment automation product comes with a comprehensive system validation feature that provides an extra layer of assurance and allows our customers to test their setups without incurring additional risks. This advanced system validation comprises a series of pre-set tests that can be customized and adapted according to customer requirements.

Systems can be tested against any combination of inputs, ensuring reliable and accurate outcomes before deployment. This helps identify potential output issues, allowing companies to make the necessary changes before production or complete instances of integration.

Air Blasting Products by Dawson-Macdonald Co., Inc.

Our automatic blast cabinets allow for the seamless integration of products into existing systems, assuring customers that the results will align with their expectations.

AutoSyst B:

Our automated-blast systems have been tested in various industries, with many reporting increased productivity and quality control thanks to their sophisticated design. Fromturntable machines for descaling parts to customized computer-controlled processes for peening, our hundreds of systems have been proven effective around the globe.

ILL885 web:

The IL-885 is the pinnacle of Empire Abrasive Equipment’s Pro-Finish® technology, featuring a durable conveyor belt that covers 9 x 72 inches. Its variable speed controls provide greater control, while adjustable parts guides can be modified to finish both tubular and flat parts.

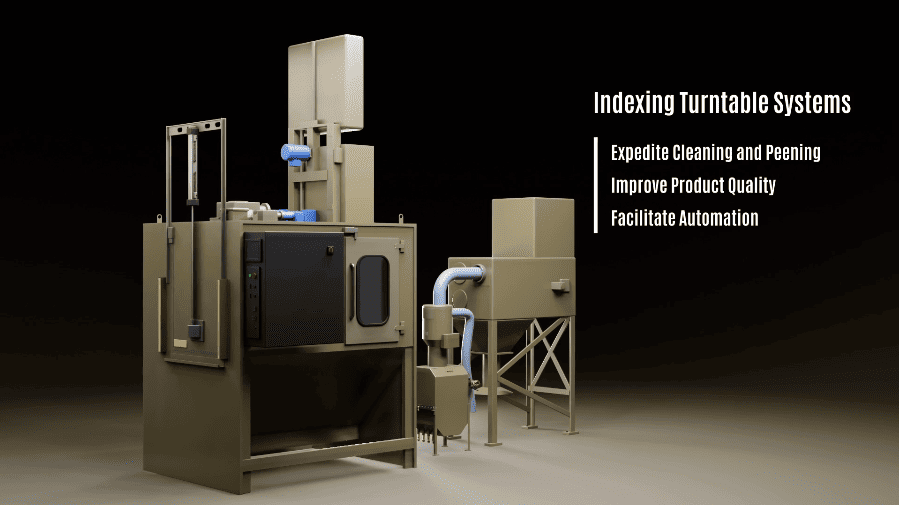

Indexing turntable:

Indexing turntable systems are an invaluable asset to industrial manufacturers, allowing for greater production efficiency. By expediting cleaning and peening processes, manufacturers can improve the quality of their products with improved accuracy levels and quicker cycles per hour.

RBT36 F Robotic Blasting Cell:

The RBT36-F Robotic Blasting Cell from Empire Abrasive Equipment makes blast and reclaim more efficient than ever. This advanced automation solution is highly customizable, making it suitable for various applications.

Industries Served

Various industries utilize automated air blasting to produce quality parts for a wide range of applications. The most common use of robotic air blasting is for metal part surface preparation to prepare the component for finishing processes.

At Dawson-Macdonald, we offer automated air blasting solutions for the following industries.

Automotive

The automotive industry uses automated air blasting systems for surface preparation of parts, such as cylinder heads, engine blocks, and transmission housings.

Manufacturing

The manufacturing industry relies on automated air blasting equipment for prepping the surfaces of metal parts, including weldments, castings, and forgings.

Aerospace

Parts and components used for aerospace applications require high precision and reliability. Automated air blasting provides the efficient surface preparation of metal aerospace parts like turbine rings and blades.

Construction

Quality materials are necessary for reliable construction projects. Therefore, the construction industry utilizes automated air blasting for the surface preparation of steel beams and other construction materials.

Marine

The marine and shipbuilding industries must meet high standards for maximum corrosion protection and have the ability to withstand harsh environmental conditions. Automated air blasting systems efficiently prepare the metal surfaces of ship deck rails and more so that they can be properly coated to resist these harsh conditions.

Air Blast Equipment by Dawson-Macdonald

Robotic air blasting eliminates the need for operators to be present in the blasting environment, which increases workplace safety and allows for continuous operation with precision and efficiency. In addition, the automated system allows the speed and nozzle path to be pre-set to deliver full coverage of the surface for maximized productivity.

With so many air blasting equipment options to choose from, you should partner with a provider that can help you select or customize the right automated system for your unique application. With over 90 years of experience in the surface preparation equipment industry, Dawson-Macdonald can help you determine the right automated blasting system for any job.

Dawson-Macdonald is the biggest and oldest distributor of surface preparation equipment in the Northeast, including abrasive blasting, dust/mist/fume collection, and shot peening. Our automated air blasting equipment is equipped with accurate flow control, automatic recovery and classification capabilities, and comprehensive system validation for enhanced results.

Contact us to learn more about our automated air blasting solutions and how we can help you choose the ideal system for your needs.

Contact Us